Design for Manufacture and Assembly

"simplicity in design, economy in production"

. If you are familiar with product design you will know that it is easy to make a design complicated, however it is quite challenging to make a complicated design simple. This is where I put in effort during the design process, because the benefits of simplicity in design are important for the whole company organization.

AJC Design Engineering ApS applies DFMA design techniques during the early design stage following the principals of good product design to facilitate easy, cost effective assembly:

Reduce part count

Reduce part types or standardisation

Elimination of adjustments

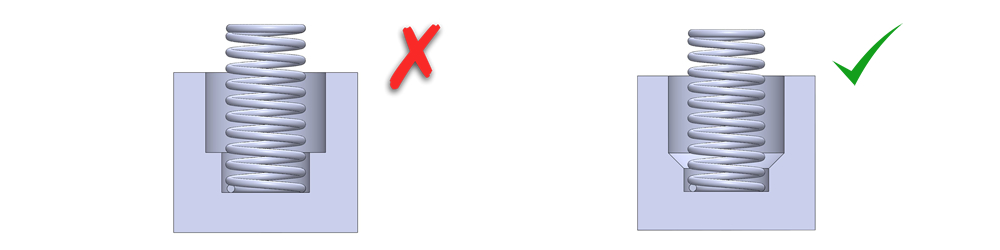

Self-alignment and self locating

Adequate access and visibility

Ease of handling of parts from bulk

Minimise reorientations during assembly

Maximise part symmetry or emphasise asymmetry

The importance of designing for assembly/manufacturing is underlined by the fact that about 70% of assembly/manufacturing costs of a part or system are determined by design decisions, with production decisions responsible for only 20%. The designer plays a key role in the development of the part or system. If designs are not designed for Assembly or Manufacturability, improvements in the assembly process will have very limited results.